Water is an indispensable resource for industrial processes, but the wastewater generated from these processes—known as effluent—is often contaminated with toxic substances, chemicals, and heavy metals. Discharging untreated effluent into the environment poses serious health and ecological hazards. That’s where an Effluent Treatment Plant (ETP) comes into play. An ETP is designed to treat and purify wastewater from industrial sources, ensuring it meets environmental standards for safe discharge or reuse.

This article provides a comprehensive look into what Effluent Treatment Plants are, how they function, their importance, technologies used, and how manufacturers like Kelvin Water Technologies Pvt. Ltd. are leading the way in providing customized ETP solutions in India.

What is an Effluent Treatment Plant?

An Effluent Treatment Plant (ETP) is a system used to treat wastewater generated from industrial activities. The effluent may contain a wide range of pollutants—such as oils, grease, chemicals, heavy metals, dyes, and suspended solids—which must be removed before the water is discharged into the environment or reused.

Unlike sewage treatment, which primarily deals with organic waste, ETPs are designed to handle complex, chemical-laden wastewater from industries such as textiles, pharmaceuticals, chemicals, food processing, refineries, and more.

How Does an Effluent Treatment Plant Work?

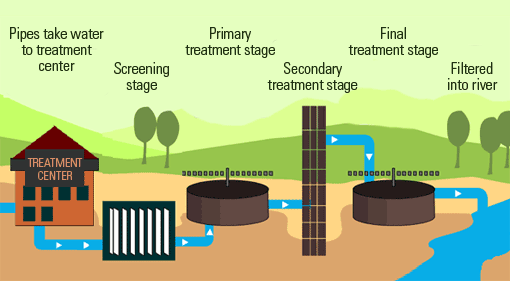

Effluent treatment is a multi-stage process that typically includes physical, chemical, and biological treatment methods to eliminate contaminants from wastewater.

1. Preliminary Treatment

- Purpose: Remove large solids, oils, and coarse particles.

- Processes:

- Screening

- Oil and grease traps

- Grit removal

2. Primary Treatment

- Purpose: Remove settleable solids and some suspended materials.

- Processes:

- Coagulation and flocculation using chemical agents

- Primary sedimentation tanks to separate sludge

3. Secondary Treatment (Biological Treatment)

- Purpose: Break down organic matter using microorganisms.

- Technologies:

- Activated Sludge Process (ASP)

- Moving Bed Biofilm Reactor (MBBR)

- Membrane Bioreactor (MBR)

- Sequential Batch Reactor (SBR)

4. Tertiary Treatment

- Purpose: Polish the treated water for reuse or safe discharge.

- Processes:

- Sand filtration

- Activated carbon filtration

- Reverse Osmosis (RO)

- UV disinfection or chlorination

5. Sludge Treatment and Disposal

- Sludge generated from treatment is thickened, dewatered (via filter press or centrifuge), and either disposed of in landfills or used as bio-compost (if non-hazardous).

Key Industrial Applications of ETPs

Effluent Treatment Plants are critical for industries that discharge complex and hazardous wastewater. Common sectors that rely on ETPs include:

✔️ Textile and Dyeing Industries

- Removes colour, dye, salts, and organic pollutants from effluent.

✔️ Pharmaceuticals and Chemicals

- Treats high COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand) wastewater containing solvents, acids, and chemicals.

✔️ Food & Beverage Industry

- Handles organic waste, fats, and biodegradable materials.

✔️ Oil Refineries & Petrochemicals

- Treats hydrocarbon-laden wastewater with oil-water separation units.

✔️ Paper and Pulp Mills

- Reduces lignin, suspended solids, and bleaching agents.

✔️ Electroplating and Metal Finishing

- Treats wastewater with high metal content like chromium, lead, zinc, and nickel.

Parameters Treated in an ETP

A well-designed ETP effectively reduces the following parameters:

| Parameter | Removal Efficiency (%) |

| BOD (Biochemical Oxygen Demand) | 85–95% |

| COD (Chemical Oxygen Demand) | 75–90% |

| TSS (Total Suspended Solids) | 90–95% |

| Heavy Metals (e.g., Cr, Pb, Ni) | 90–99% |

| pH Balance | Adjusted to neutral (6.5–8.5) |

| Oil & Grease | 85–95% |

🔧 Types of ETP Based on Operation

1. Batch Process ETP

- Suitable for small-scale industries

- Wastewater is collected and treated in batches

2. Continuous Flow ETP

- Ideal for large industries with ongoing wastewater discharge

- Requires continuous monitoring and automation

| Technology | Description |

| Coagulation/Flocculation | Chemical addition to agglomerate fine particles |

| Dissolved Air Flotation (DAF) | Removes suspended solids, oil, and grease |

| MBBR | Biological treatment using biofilm media |

| SBR | Time-based batch biological process |

| MBR | Combines biological treatment with membrane filtration |

| Reverse Osmosis (RO) | Advanced purification for reuse |

| Activated Carbon Filter | Removes odor, color, and organic pollutants |

Importance and Benefits of ETPs

✔️ Environmental Protection

ETPs prevent the release of harmful contaminants into water bodies, protecting aquatic life and preventing water pollution.

✔️ Regulatory Compliance

Industries must meet the discharge norms set by CPCB (Central Pollution Control Board) and State Pollution Control Boards (SPCBs). Non-compliance can result in heavy fines and shutdowns.

✔️ Water Reuse and Resource Recovery

Treated effluent can be reused for non-potable purposes like:

- Boiler feed water

- Cooling towers

- Gardening and irrigation

- Floor washing and flushing

✔️ Sustainable Operations

ETPs help industries adopt sustainable manufacturing practices and contribute to zero-liquid discharge (ZLD) goals.

✔️ Improved Public Image

Environmental responsibility enhances brand image and helps attract environmentally conscious investors and customers.

Kelvin Water Technologies Pvt. Ltd. – Trusted ETP Manufacturer in India

When it comes to designing, manufacturing, and installing advanced Effluent Treatment Plants, Kelvin Water Technologies Pvt. Ltd. is a name synonymous with reliability, quality, and innovation.

🔹 Company Overview

- Government-registered and ISO 9001:2015 certified

- Over a decade of experience in wastewater and zero-liquid discharge systems

- Expert team of engineers, chemists, and technicians

- Specializes in customized ETP solutions for all industrial sectors

🔧 What Kelvin Offers

- Design & Engineering

- Manufacturing and Supply

- Installation and Commissioning

- Operation & Maintenance (O&M)

- Annual Maintenance Contracts (AMC)

- Pollution Control Board approvals assistance

Available ETP Formats

| Format | Description |

| Skid-Mounted ETP | Compact and ready-to-install |

| Containerized ETP | Portable systems for remote sites |

| Civil-Based ETP | For large-scale, permanent installations |

Conclusion

An Effluent Treatment Plant is an essential part of any responsible industrial operation. It ensures safe disposal of harmful wastewater, promotes resource recovery, and supports environmental sustainability. With the rise of strict environmental regulations and growing awareness of water conservation, the demand for high-efficiency ETP systems continues to increase.

By partnering with a trusted manufacturer like Kelvin Water Technologies Pvt. Ltd., industries can ensure reliable, compliant, and cost-effective wastewater management—paving the way for a cleaner, greener future.